Спасибо, что помогаете стать нам лучше

Elemental analysis in motor oils and additives.

Engine oils are designed to protect and prevent wear of parts. The performance characteristics and durability of the engine depend on the quality of the oil. To improve the oils, various additives are added to them – organometallic compounds with anti-wear, anti-pressure, antioxidant, anti-corrosion, etc. functions.The content of elements in additives must be monitored both during the production of oils, including for quality control of finished products, and during operation to assess the production of additives.

One of the documents establishing methods for the quantitative determination of elements in oils is ASTM D 6481-14* «Standard test method for determination of phosphorus, sulfur, calcium and zinc in lubrication oils by energy dispersive X-ray fluorescence spectroscopy», according to which energy-dispersive X-ray fluorescence spectrometers are used in the determination.

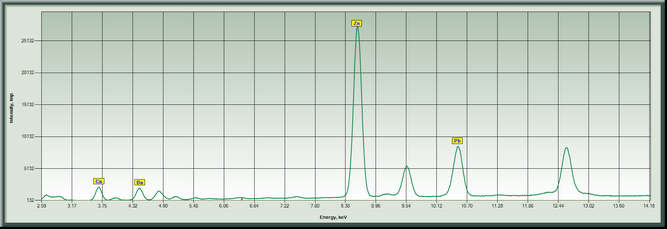

Прибор ЭКРОС XRF-9710 PEARL is a compact X-ray fluorescence spectrometer and can be used to determine phosphorus, sulfur, calcium, zinc and other elements in oils.

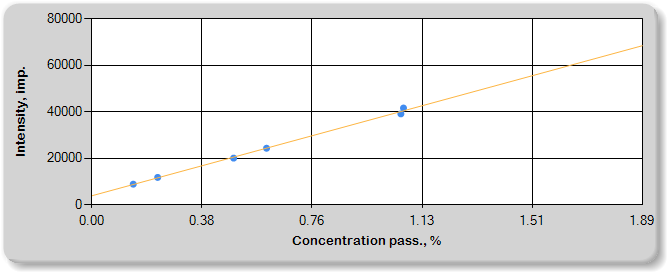

The development of a methodology for determining these elements has begun, including calibration of the device to accurately determine the elements.

The results show the possibility of using X-ray fluorescence spectrometers of production

ECROSKHIM LTD for oil quality control.